Cleaner Air Along the C&O Canal, Smarter Water Use in Commercial Buildings

By • April 11, 2016 0 1385

This week, parts of Washington, D.C., took steps to improve their environment and better their water sustainability with odor-scrubbing facilities and new water treatment technology.

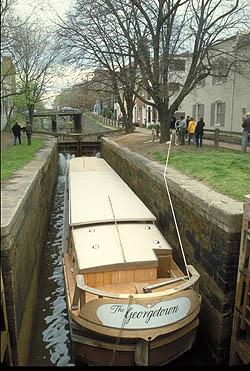

The smell of sewer gas along the C&O Canal will soon come to an end. On June 4, the District of Columbia Water and Sewer Authority cut the ribbon for its first odor-scrubbing facility next to Fletcher’s Boathouse.

“I’m happy, definitely and especially because of the areas where there are kids,” said Fatou Sanyang, a Georgetown mom, who spends her mornings walking around the canal with her son.

Although the initiative began in the 1990s, it took years and more than 40 permits to break ground of the first facility in 2010, leading to the beginning of D.C.’s Fresh Air Operation. The project includes six buildings with scrubbers along the 50-mile-long Potomac Interceptor, which carries approximately 50 million gallons of sewage per day. Three of the buildings are under construction in Maryland, and two others, soon to begin operation, in Virginia, according to Pamela Mooring, communications manager at the D.C. Water and Sewer Authority.

The buildings will control odors by sucking the sewer gas into the scrubber, getting rid of the smelly gasses and releasing non-odorous air back outside. Two of these buildings will also have public restrooms.

In addition, an effort to build sustainability by cutting water, electricity and toxic chemical use in commercial buildings began in downtown D.C.

The Willard InterContinental on Pennsylvania Avenue, along with property developers and owners Lerner Enterprise, Carr Properties, and W.C. Smith, are now working with Silver Bullet, a company that provides an innovative approach to the use of cooling towers.

The system works in the following way: the processor, which combines UV treatment and additional elements, breaks the oxygen molecule and sends it to the cooling tower’s water supply, where it is combined to form hydrogen peroxide (H2O2). The new chemical compound prevents bacterial growth and corrosion, and it also reduces water consumption. At the same, this process requires very little electricity, becoming a more efficient and lower maintenance option, according to Carlton Diehl, regional vice president of Silver Bullet.

“It’s an amazingly elegant way of using chemistry,” Diehl said. “You can see the savings from the very first day.”

Innovative, toxic-free and efficient technology is on the rise to help big and small businesses reduce their costs and help protect the environment. Projects like Fresh Air Operation and Silver Bullet’s water treatment technology are examples that should regularly benefit residents and visitors of the District of Columbia.